Years of experience fixing and creating solutions for common thermoplastic manufacturing issues

Burn marks happen because the gases from the melt get trapped and cause dieseling, our Silaplast™ Thermoplastic Additive will fix this issue.

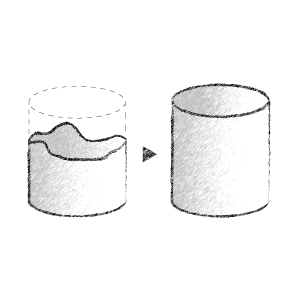

Silaplast™ Thermoplastic Additive will help change the melt rheology and will allow the part to be packed out better which will greatly minimize the occurrence of sink marks.

Adding Silaplast™ Thermoplastic Additive master-batch to the resin at a higher percentage provides a smoother surface. This surface is soft and silky to touch and provides a better-perceived quality to the finished part.

Addition of Silaplast™ Thermoplastic Additive changes the COF (Coefficient of Friction) on the surface and minimizes the friction between the part and the mold. This allows the parts to not stick as much to the mold and also eject easier. Robust option to address BSR (Buzz Squeak Rattle) and NVH (Noise Vibration Harshness) issues in automotive components.

Silaplast™ Thermoplastic Additive will help change the melt rheology and will allow the part to be packed out better which will greatly minimize the occurrence of sink marks.

The addition of Silaplast™ Thermoplastic Additive allows the slip planes of the melt to slide better against each other. This helps in filling out the part faster before the melt viscosity starts increasing. This also gives the opportunity to the melt to fill the part completely thereby minimizing the opportunity for non-fills and short shots.

Adding Silaplast™ Thermoplastic Additive will allow for lower barrel and mold temperatures which lowers energy costs & carbon footprint. This allows for a higher percentage usage of recycled and regrind material in the resin matrix. It will also lower the cycle time of each part which improves manufacturing efficiency.

Silaplast™ Thermoplastic Additive will get dispersed uniformly in the resin matrix. This resin surface and matrix becomes more yielding and hence provides a greater resistance to scratching and scuffing of the surface.

Adding Silaplast™ Thermoplastic Additive in the resin minimized the wear and tear and galling of the barrels and screws. This leads to lower maintenance costs in the form of less frequent maintenance and longer performance life of the barrels, screws and check rings.

Silaplast™ Thermoplastic Additive will allow for faster and even dispersion of colorant pigment in the resin matrix. This leads to smaller purges and faster process stabilization.

Call us today, or fill out our contact form, we are available to answer your questions and help find the right custom engineered siloxane formulation solution for your thermoplastic product or manufacturing.

Contact Us